본문

| Features |

MQW Series Jet Mill

Single Rotor / Multiple Rotor

- More fineness

- With Classifying Rotor, easy to adjust

- Large capacity, Up to 57T/H

- Wide range of applications

- Single Rotor / Multiple Rotor

- 325-10000 mesh (45 μm-1 μm)

MQPW Series Jet Mill

- Multi-nozzle structure, no grinding dead zone

- Ceramicized, no pollution

- Stronger deagglomeration ability

- Applicable: Battery materials, chemical

- 100-10000 mesh (150μm-1μm)

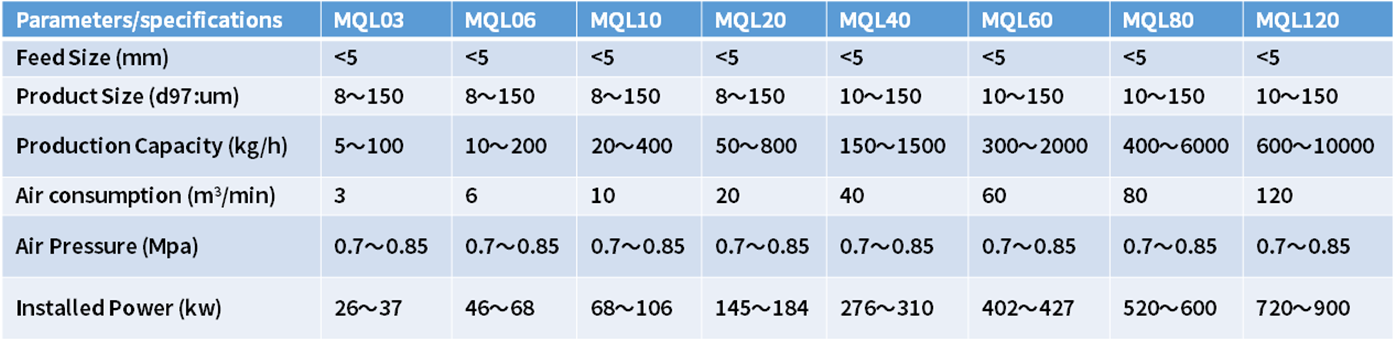

MQL Series Jet Mill

- Vertical impeller, single rotor

- Secondary air design, high energy utilization rate

- Large capacity

- Wide range of applications

- 325-5000 mesh (45μm-2.5μm)

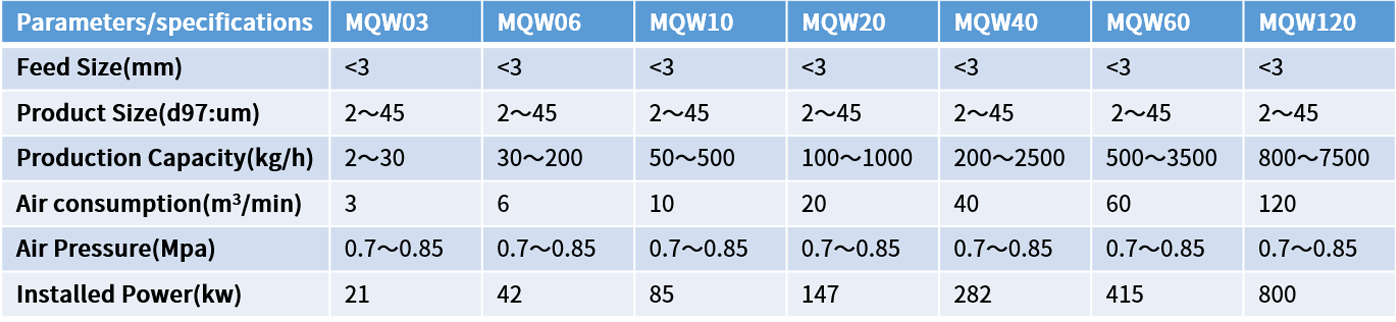

MQW Series Jet Mill

Single Rotor / Multiple Rotor

- Features:

Automatic PLC programming control, easy to adjust, easy to operate. - Applicable:

Widely used in chemical, mineral, metallurgy, abrasives, ceramics, refractory materials, medicines, pesticides, food, health products, new materials and other industries.

Jet Mill works with cyclone separator, dust collector and suction fan to form a complete classifying system. Compressed air flow after filtration and drying would go into milling chamber from nozzles, and meet in the center area, where material would be impacted and ground and sheared. Milled powder would go up to the classifying chamber by the air flow from suction fan. The high-speed rotation of classifier wheel would create a strong centrifugal force to separate coarse powder and fine powder. Qualified fine powder would go through the wheel vane then into the cyclone separator or dust collector, while mixture of coarse powder and fine powder would fall down to the milling chamber to be milled again.

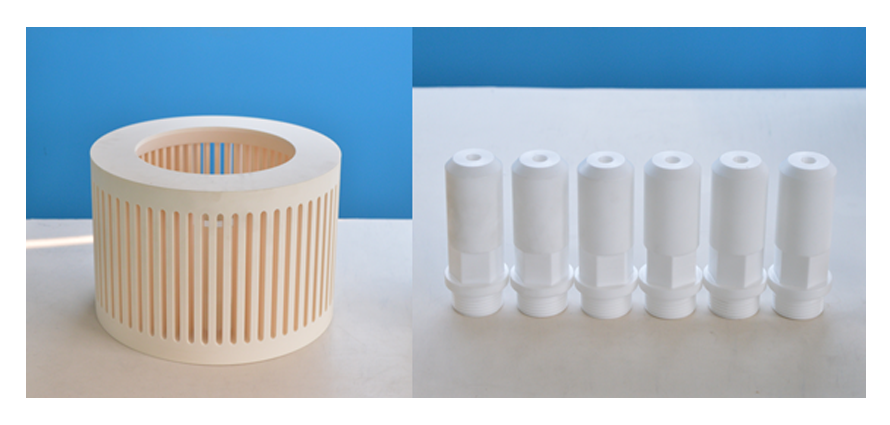

High Precision Classifying Rotor

High-precision classifying rotors ensure precise apex cutting for demanding product requirements.World-class ceramic rotor with line speeds up to 65m/s. High-precision and high-purity ultra-fine powder classifying can achieve a specific gravity of 26g/cm3, D100: 8um.

- More fineness

- With Classifying Rotor, easy to adjust

- Large capacity, Up to 57T/H

- Wide range of applications

- Single Rotor / Multiple Rotor

- 325-10000 mesh (45 μm-1 μm)

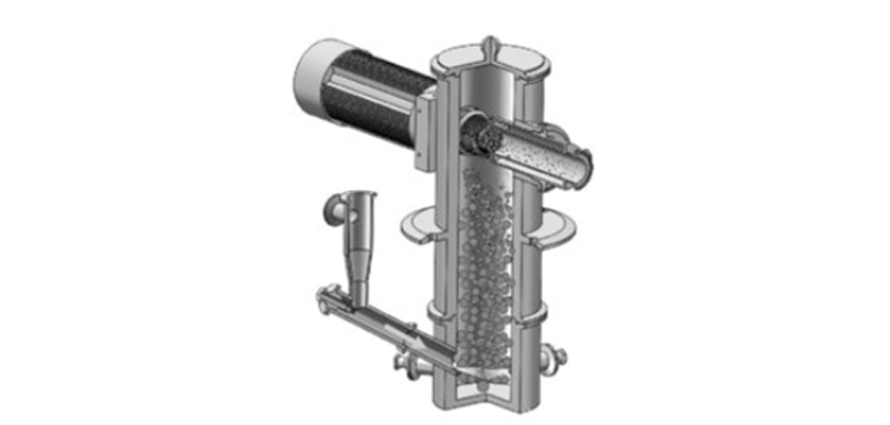

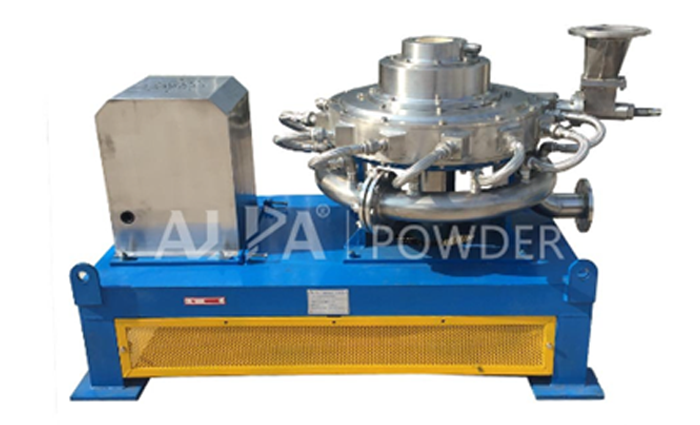

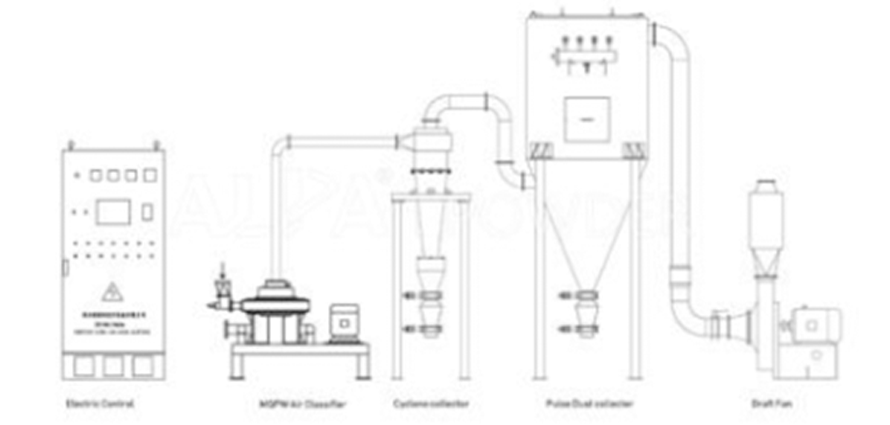

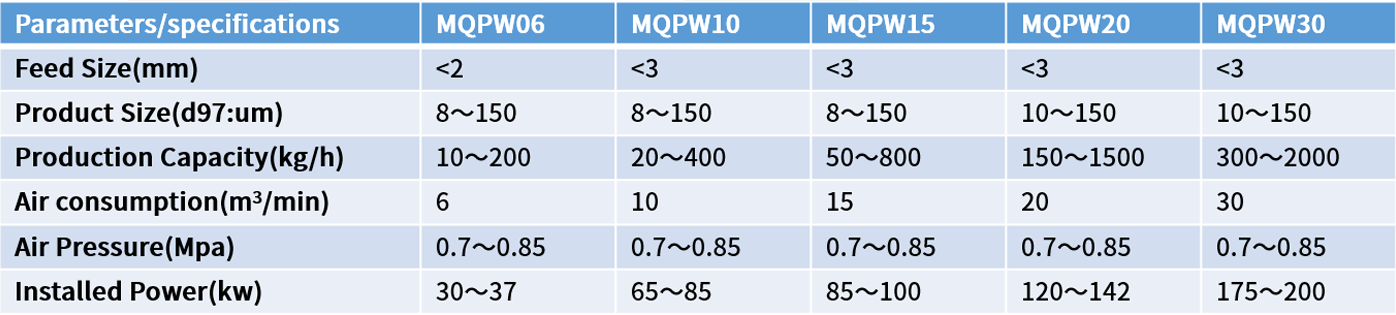

MQPW Series Jet Mill

Adopting German technology, high-precision jet mill, continuous technological innovation and upgrading, suitable for 100-10000 mesh (150μm-1μm).

- Features:

Built-in classifying, high energy efficiency, energy saving is better than traditional jet mills, own stronger deagglomeration ability compared with traditional fluidized bed jet mill. - Applicable:

Widely used in chemical, single crystal ternary materials, small particles of lithium cobalt oxide, lithium hydroxide, lithium carbonate and other industries.

Jet Mill works with cyclone separator, dust collector and suction fan to form a complete classifying system. Compressed air flow after filtration and drying would go into milling chamber from nozzles, and meet in the center area, where material would be impacted and ground and sheared. Milled powder would go up to the classifying chamber by the air flow from suction fan. The high-speed rotation of classifier wheel would create a strong centrifugal force to separate coarse powder and fine powder. Qualified fine powder would go through the wheel vane then into the cyclone separator or dust collector, while mixture of coarse powder and fine powder would fall down to the milling chamber to be milled again.

Built-in classifying wheel

Built-in classifying wheel for high cutting accuracy.

Multi-nozzle structure

No grinding blind zone, high energy utilization

- Multi-nozzle structure, no grinding dead zone

- Ceramicized, no pollution

- Stronger deagglomeration ability

- Applicable: Battery materials, chemical

- 100-10000 mesh (150μm-1μm)

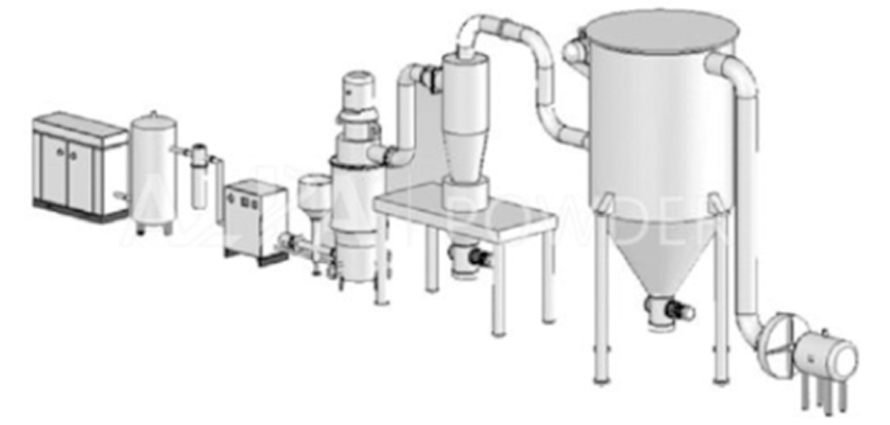

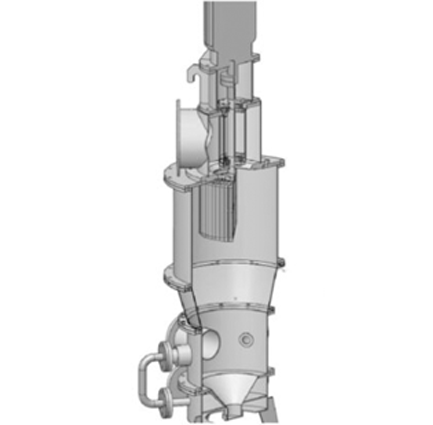

Jet Mill-MQL

Adopting German technology, high-precision jet mill, continuous technological innovation and upgrading, suitable for 325-5000 mesh (45μm-2.5μm).

- Features:

Less investment and energy saving, automatic PLC programming control, easy to adjust, easy to operate. - Applicable:

widely used in chemical, mineral, metallurgy, abrasives, ceramics, refractory materials, medicines, pesticides, food, health products, new materials and other industries.

Jet Mill works with cyclone separator, dust collector and suction fan to form a complete classifying system. Compressed air flow after filtration and drying would go into milling chamber from nozzles, and meet in the center area, where material would be impacted and ground and sheared. Milled powder would go up to the classifying chamber by the air flow from suction fan. The high-speed rotation of classifier wheel would create a strong centrifugal force to separate coarse powder and fine powder. Qualified fine powder would go through the wheel vane then into the cyclone separator or dust collector, while mixture of coarse powder and fine powder would fall down to the milling chamber to be milled again.

Vertical single rotor, high efficiency

Vertical impeller, single rotor for large production capacity, vertical single rotor structure, can meet different product requirements, high efficiency and low investment.

Adopt SKF bearing

SKF bearings make the drive run more smoothly.

- Vertical impeller, single rotor

- Secondary air design, high energy utilization rate

- Large capacity

- Wide range of applications

- 325-5000 mesh (45μm-2.5μm)